Introduction

Nano ceramic coating is the most advanced form of paint protection available today, using nanoscale silicon dioxide particles that chemically bond with your car’s clear coat to create an exceptionally durable protective layer. This technology has revolutionized how car enthusiasts and professionals approach long-term vehicle surface protection, moving far beyond traditional wax and sealants.

This guide covers everything you need to understand about ceramic coating technology, application methods, coating types, and maintenance requirements. While we explore the science and practical implementation of nano coatings, specific brand recommendations fall outside our scope. Instead, we focus on helping you make informed decisions based on your needs. Whether you’re a vehicle owner seeking superior protection, a detailing enthusiast looking to apply your first coating, or a professional detailer expanding your service offerings, this comprehensive resource addresses your goals.

Direct answer: Nano ceramic coating is a liquid silicon dioxide-based polymer that chemically bonds at the molecular level with your vehicle’s paint surface, creating a semi-permanent protective layer that typically lasts 2-5 years with proper care, offering protection against UV rays, contaminants, and environmental damage.

After reading this guide, you will gain:

- Clear understanding of how nano ceramic technology creates molecular-level protection

- Knowledge to choose between professional-grade coating and consumer DIY options

- Proper application techniques and surface preparation protocols

- Maintenance strategies that keep your coating in tip-top shape

- Insight into long-term benefits, including durability, appearance preservation, and reduced upkeep

Table of Contents

Understanding Nano Ceramic Coating Technology

Nano ceramic coating functions as a silicon dioxide-based liquid polymer that transforms your vehicle’s exterior into a highly protected surface. Unlike traditional wax that sits on top of the paint, a nano coating penetrates microscopic imperfections in your clear coat, forming chemical bonds that create a unified protective barrier.

The technology leverages nanotechnology principles, in which particles ranging from 1 to 100 nanometers integrate directly into your car paint. This molecular bonding process involves electrostatic attractions and covalent bonds, embedding the ceramic formula permanently into surface irregularities. The result is a dense, interlocking network that delivers mechanical strength approaching the resilience of solid quartz.

The ideal application temperature for nano ceramic coatings is generally between 50°F and 80°F (10°C–27°C).

The application of nano ceramic coatings requires the surface to be free of oxidation and swirl marks.

What Does a Nano Ceramic Coating Do?

nano ceramic coating serves as a sacrificial layer between your vehicle’s factory paint and the harsh environment it faces daily. This protective coating shields against UV rays that cause oxidation and fading, prevents chemical etching from bird droppings and tree sap, and creates a barrier against road salt, grime, and other contaminants.

The coating fills microscopic porous surfaces in your clear coat, creating an exceptionally smooth surface that repels water, dirt, and dust. This enables what detailing professionals call the “self-cleaning effect”—water beads and rolls off the surface, carrying contaminants away and dramatically reducing the effort needed to maintain your vehicle’s appearance.

Silicon Dioxide (SiO2) Foundation

Silicon dioxide serves as the primary protective ingredient in genuine ceramic coatings, distinguishing true nano ceramics from polymer-based alternatives. SiO2 creates a glass-like hardness often marketed at 9H on the pencil hardness scale, though independent testing shows variation depending on application thickness and curing conditions.

This silica foundation delivers the durability that makes ceramic coating so effective against scratches and swirl marks. The molecular structure of silicon dioxide enables thermal stability across extreme temperatures without degradation, protecting your car whether parked under direct sunlight or facing winter conditions.

Hydrophobic Properties

Hydrophobic surface characteristics define the water-beading effect that makes nano ceramic coating so distinctive. When properly applied, the coating creates surface tension exceeding 110-degree water contact angles, causing water droplets to form tight beads rather than sheeting across the paint.

This hydrophobic behavior directly enables self-cleaning capabilities. Rainwater or wash water lifts and carries away dust, dirt, and grime rather than leaving residue behind. The relationship between surface tension and contaminant repulsion means your vehicle stays cleaner longer between washes, reducing maintenance time and the risk of wash-induced scratches.

Understanding these hydrophobic properties sets the foundation for appreciating the practical benefits different coating types deliver.

Types and Applications of Nano Ceramic Coatings

Building on the technology fundamentals, ceramic coatings fall into distinct categories based on application complexity, durability expectations, and intended use cases. Choosing the right coating type significantly impacts both the level of protection and long-term satisfaction.

Professional-Grade Coatings

Professional-grade coating products deliver the highest level of protection available, typically offering 5-10 years of durable coverage when applied adequately by certified installers. These formulations contain higher SiO2 concentrations and often incorporate multiple-layer systems—sometimes 5-10 coats—to achieve maximum hardness and thickness.

Industrial-grade nano ceramic coatings can withstand extreme temperatures ranging from -50°F to 2,200°F.

Nano ceramic coating is infused with microscopic particles like silicon dioxide and titanium dioxide that create a durable, protective layer.

Professional application requires specialized training, controlled environmental conditions, and precise technique. Installers must complete manufacturer certification processes to access these products and offer warranty coverage. The investment typically ranges from $500 to $2000 for complete vehicle treatment, justified by the superior protection and longevity compared to consumer alternatives.

These coatings are highly recommended for car enthusiasts with high-value vehicles, for those seeking ultimate protection with minimal personal involvement, or for anyone seeking manufacturer-backed warranties that guarantee performance.

Consumer-Grade DIY Coatings

Consumer-grade ceramic coatings bring nano-protection technology to the home detailer, with user-friendly formulations designed for 1-3-year durability. These products simplify the application process while maintaining meaningful protection against UV rays, oxidation, and environmental contaminants.

The application process becomes extremely easy compared to professional systems—most products come in a bottle with included applicators and straightforward instructions. While prep work remains critical, the coating itself goes on in a simple process that weekend detailers can master.

Performance expectations should remain realistic. Consumer coatings deliver genuine protection but won’t match the hardness, durability, or longevity of professional installations. For those willing to reapply every few months to a few years, DIY options offer excellent value while teaching valuable polishing and surface-preparation skills.

Specialized Coating Variations

The market now offers specialized nano-coating formulations tailored to specific needs. Graphene-enhanced ceramic coatings incorporate carbon nanomaterial structures to enhance heat dissipation, reduce water spotting from evaporation, and improve durability in hot climates.

Marine-grade formulations address the unique challenges of boat and watercraft applications, protecting against saltwater corrosion while maintaining hull slickness. These products withstand constant exposure to water and the abrasive elements present in marine environments.

When choosing coating type, consider your vehicle usage, local environment, maintenance commitment, and budget. A truck frequently exposed to harsh off-road conditions has different protection needs than a garage-kept sports car. This understanding enables wise investment in the proper protection level.

With the coating type selected, proper application becomes the difference between exceptional results and disappointing performance.

Application Process and Implementation

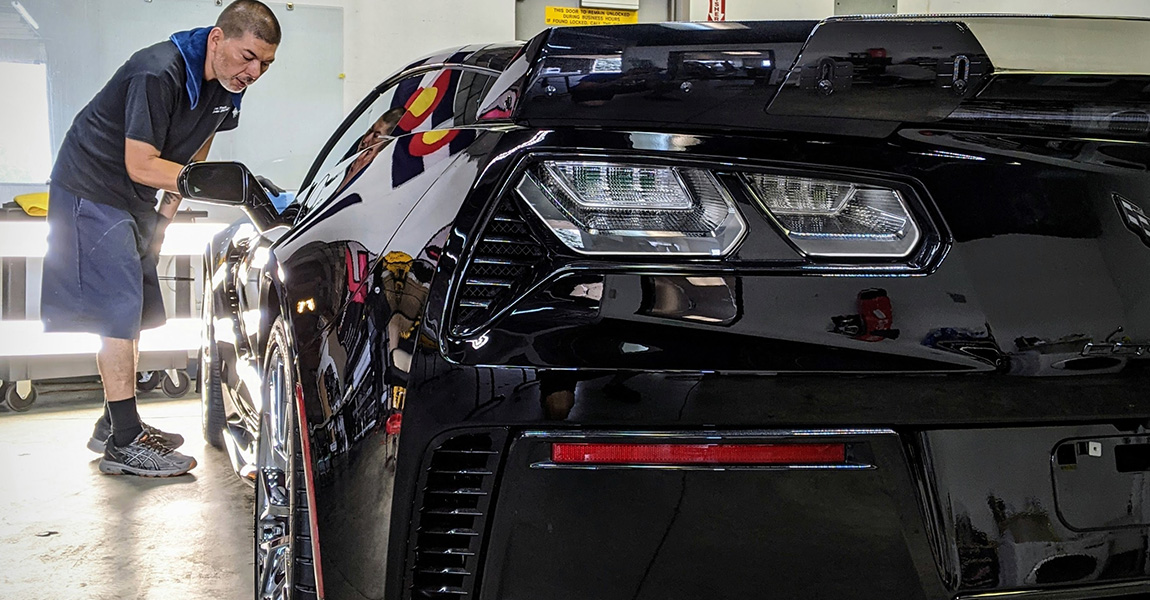

Successful ceramic coating application depends entirely on meticulous surface preparation and proper technique. Even the finest professional-grade coating fails when applied to improperly prepared paint—the formula cannot bond with contaminated or damaged surfaces.

Surface Preparation Protocol

Surface prep work represents 80% of a successful coating installation. Rushing or skipping steps guarantees poor results regardless of product quality.

- Thorough washing and decontamination: Start with a multi-stage wash using pH-neutral car shampoo, then apply a clay bar treatment to remove embedded contaminants such as iron particles, rail dust, and industrial fallout from the surface.

- Paint correction: Address existing swirl marks and scratches through polishing. The nano coating will lock in the current paint condition—imperfections beneath the coating remain visible and protected permanently.

- Final cleaning with isopropyl alcohol: Wipe the entire vehicle with IPA solution (typically 20-30%) to remove any oils, wax residue, or polishing compounds. Any silicone contamination prevents proper bonding.

- Surface inspection under proper lighting: Use LED inspection lights to verify complete contamination removal. Check panel by panel before proceeding to coating application.

Application Method Comparison

Criterion | Microfiber Applicator Method | Cross-Hatch Foam Method |

|---|---|---|

Application Tool | Suede microfiber wrapped applicator | High-density foam block |

Coverage Pattern | Panel-by-panel, single direction | Overlapping cross-hatch pattern |

Flash Time | 30-60 seconds before removal | 1-2 minutes before removal |

Durability Result | Consistent thin layers | Slightly thicker coverage |

Best For | Beginners, smaller vehicles | Experienced users, larger surfaces |

For first-time applicators, the microfiber method proves more forgiving. Work one small section at a time, allowing the coating to flash before buffing away with a clean microfiber towel. The cross-hatch technique delivers more uniform coverage but requires confidence in proper timing.

Allow adequate cure time per manufacturer specifications—typically 24-48 hours before water exposure and 7-14 days before washing. Proper curing dramatically impacts long-term protection and durability.

Common Challenges and Solutions

Even experienced detailers encounter issues during ceramic coating application and maintenance. Understanding these challenges beforehand enables prevention and quick correction.

High Spots and Streaking During Application

High spots appear as rainbow-colored or hazy areas where excess coating remained too long before removal. Prevent this issue by applying the product thinly and evenly, then removing it immediately once the product flashes.

If high spots develop, act immediately—wipe with a clean microfiber dampened slightly with isopropyl alcohol. Dried high spots require polishing to remove, which compromises the coating in that area. Always inspect under proper lighting during application to catch problems early.

Premature Coating Degradation

Coating breaking down before its expected lifespan typically results from improper maintenance. Use only pH-neutral car shampoo for regular washing, avoiding harsh chemicals that strip the coating’s hydrophobic layer.

Avoid automatic car washes entirely—the brushes and aggressive chemicals dramatically accelerate coating wear. Hand washing with proper technique maintains your coating’s protection for the full expected lifespan, keeping everything in tip-top shape.

Water Spotting on Coated Surfaces

Mineral deposits from hard water or rain can leave spots even on ceramic-coated surfaces. While the coating prevents etching, dried minerals create unsightly marks that reduce the surface’s appearance and hydrophobic performance. Learn how to remove water spots on ceramic coating with expert tips for a flawless finish.

Remove water spots promptly with a distilled-water rinse or a dedicated spot remover. Prevention works best—dry your vehicle immediately after washing and park in covered areas when rain is expected. These simple steps maintain your coating’s self-cleaning properties and shine.

How Long Does Nano Ceramic Car Coating Last?

Nano ceramic coating typically lasts 2–5 years on a daily-driven vehicle, depending on the product quality, how well it’s applied, and maintenance (washing habits, exposure to sun/salt, and using a topper or maintenance spray).

Conclusion and Next Steps

Nano ceramic coating is a premium paint protection investment that delivers measurable benefits in surface durability, reduced maintenance, and long-term appearance preservation. The technology’s molecular bonding creates protection that traditional wax and sealants cannot match, shielding your vehicle from UV rays, chemicals, scratches, and environmental contaminants for years rather than weeks.

Immediate next steps:

- Assess your vehicle’s current condition—determine what paint correction is needed before coating

- Choose between professional installation and DIY application based on your experience level and budget

- Schedule your application timeline, ensuring adequate time for prep work and cure periods

If your experience level or vehicle value warrants it, consider professional installation through a certified professional detailer who offers warranty-backed work. For enthusiasts comfortable with detailed surface prep, quality consumer-grade products deliver excellent long-term protection at accessible price points.

Related topics worth exploring include paint protection film for high-impact areas, maintenance products specifically formulated for ceramic-coated surfaces, and advanced detailing techniques that complement your coating investment.

Additional Resources

Essential DIY Application Toolkit:

- Two-bucket wash system with grit guards

- Quality clay bar kit and lubricant

- Dual-action polisher for paint correction

- Isopropyl alcohol (minimum 70%)

- Multiple high-quality microfiber towels

- LED inspection light

- Suede-wrapped applicators

Maintenance Product Considerations:

- pH-neutral, ceramic-safe car shampoo for regular wash

- SiO2 spray sealant for boosting hydrophobic properties

- Dedicated glass cleaner compatible with coated surfaces

- Soft wash mitts designed for coated vehicles

Professional Resources:

- Manufacturer certification programs verify installer competence

- Industry organizations maintain directories of certified coating shops

- Online communities provide helpful guidance for DIY applicators seeking to maintain their ceramic protection properly

Have questions about nano ceramic coating or want help choosing the right level of protection for your vehicle? Contact us today to learn more about coating options, durability, pricing, and the best prep process for long-lasting results. Call, message, or request a quote—we’re here to help you protect your paint, boost gloss, and keep your car looking its best.

WHAT OUR CLIENTS ARE SAYING